1. Product Principles and Microstructural Characteristics of Alumina Ceramics

1.1 Make-up, Pureness Grades, and Crystallographic Quality

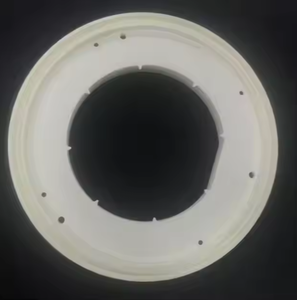

(Alumina Ceramic Wear Liners)

Alumina (Al Two O TWO), or light weight aluminum oxide, is among one of the most commonly used technical porcelains in commercial design as a result of its outstanding equilibrium of mechanical stamina, chemical security, and cost-effectiveness.

When crafted into wear liners, alumina ceramics are usually produced with purity degrees ranging from 85% to 99.9%, with greater pureness representing improved hardness, use resistance, and thermal performance.

The leading crystalline stage is alpha-alumina, which embraces a hexagonal close-packed (HCP) framework characterized by solid ionic and covalent bonding, contributing to its high melting point (~ 2072 ° C )and low thermal conductivity.

Microstructurally, alumina porcelains contain fine, equiaxed grains whose dimension and circulation are controlled throughout sintering to optimize mechanical residential properties.

Grain dimensions generally vary from submicron to a number of micrometers, with finer grains typically improving fracture strength and resistance to fracture proliferation under abrasive packing.

Small additives such as magnesium oxide (MgO) are commonly introduced in trace amounts to prevent abnormal grain development throughout high-temperature sintering, guaranteeing uniform microstructure and dimensional security.

The resulting product shows a Vickers solidity of 1500– 2000 HV, dramatically surpassing that of set steel (commonly 600– 800 HV), making it extremely resistant to surface deterioration in high-wear settings.

1.2 Mechanical and Thermal Performance in Industrial Issues

Alumina ceramic wear linings are picked largely for their outstanding resistance to unpleasant, abrasive, and gliding wear mechanisms widespread wholesale material handling systems.

They possess high compressive stamina (up to 3000 MPa), great flexural toughness (300– 500 MPa), and exceptional tightness (Young’s modulus of ~ 380 GPa), allowing them to stand up to intense mechanical loading without plastic contortion.

Although naturally weak compared to metals, their low coefficient of rubbing and high surface area hardness minimize bit adhesion and minimize wear prices by orders of size relative to steel or polymer-based alternatives.

Thermally, alumina maintains architectural stability as much as 1600 ° C in oxidizing atmospheres, permitting use in high-temperature handling environments such as kiln feed systems, central heating boiler ducting, and pyroprocessing devices.

( Alumina Ceramic Wear Liners)

Its reduced thermal growth coefficient (~ 8 × 10 ⁻⁶/ K) adds to dimensional security throughout thermal cycling, minimizing the danger of breaking because of thermal shock when properly installed.

In addition, alumina is electrically shielding and chemically inert to a lot of acids, alkalis, and solvents, making it suitable for harsh atmospheres where metal linings would deteriorate quickly.

These consolidated homes make alumina porcelains suitable for protecting important facilities in mining, power generation, concrete manufacturing, and chemical processing markets.

2. Manufacturing Processes and Layout Integration Techniques

2.1 Forming, Sintering, and Quality Assurance Protocols

The manufacturing of alumina ceramic wear linings includes a sequence of precision manufacturing steps designed to attain high thickness, marginal porosity, and regular mechanical performance.

Raw alumina powders are processed via milling, granulation, and developing strategies such as dry pushing, isostatic pressing, or extrusion, depending on the wanted geometry– tiles, plates, pipelines, or custom-shaped sections.

Green bodies are then sintered at temperatures in between 1500 ° C and 1700 ° C in air, advertising densification with solid-state diffusion and achieving family member densities surpassing 95%, typically approaching 99% of theoretical thickness.

Complete densification is crucial, as residual porosity works as stress concentrators and accelerates wear and fracture under service problems.

Post-sintering operations might consist of diamond grinding or washing to accomplish limited dimensional resistances and smooth surface area finishes that decrease rubbing and particle trapping.

Each set undertakes rigorous quality control, consisting of X-ray diffraction (XRD) for phase evaluation, scanning electron microscopy (SEM) for microstructural evaluation, and hardness and bend screening to verify conformity with international criteria such as ISO 6474 or ASTM B407.

2.2 Placing Techniques and System Compatibility Factors To Consider

Effective combination of alumina wear linings right into industrial tools requires mindful attention to mechanical attachment and thermal growth compatibility.

Usual installment techniques include glue bonding making use of high-strength ceramic epoxies, mechanical attaching with studs or supports, and embedding within castable refractory matrices.

Adhesive bonding is widely utilized for level or carefully curved surfaces, providing consistent stress distribution and vibration damping, while stud-mounted systems permit simple replacement and are liked in high-impact zones.

To fit differential thermal expansion in between alumina and metallic substratums (e.g., carbon steel), crafted spaces, flexible adhesives, or compliant underlayers are included to avoid delamination or breaking throughout thermal transients.

Designers need to also consider edge defense, as ceramic tiles are prone to breaking at revealed corners; solutions include diagonal edges, metal shadows, or overlapping ceramic tile setups.

Correct installment makes certain long life span and takes full advantage of the safety feature of the liner system.

3. Put On Mechanisms and Performance Evaluation in Service Environments

3.1 Resistance to Abrasive, Erosive, and Impact Loading

Alumina ceramic wear liners excel in settings dominated by 3 key wear systems: two-body abrasion, three-body abrasion, and bit erosion.

In two-body abrasion, difficult bits or surface areas straight gouge the lining surface area, a typical event in chutes, receptacles, and conveyor shifts.

Three-body abrasion entails loose particles caught in between the liner and relocating material, leading to rolling and scratching activity that progressively eliminates product.

Abrasive wear happens when high-velocity bits impinge on the surface, particularly in pneumatically-driven communicating lines and cyclone separators.

As a result of its high hardness and low fracture durability, alumina is most effective in low-impact, high-abrasion scenarios.

It executes incredibly well against siliceous ores, coal, fly ash, and concrete clinker, where wear rates can be minimized by 10– 50 times contrasted to moderate steel liners.

Nevertheless, in applications entailing duplicated high-energy impact, such as main crusher chambers, crossbreed systems incorporating alumina tiles with elastomeric supports or metallic shields are often employed to soak up shock and prevent fracture.

3.2 Field Screening, Life Process Evaluation, and Failing Setting Assessment

Efficiency analysis of alumina wear linings entails both laboratory testing and field monitoring.

Standard tests such as the ASTM G65 dry sand rubber wheel abrasion examination give comparative wear indices, while tailored slurry disintegration rigs mimic site-specific conditions.

In industrial settings, use price is commonly determined in mm/year or g/kWh, with service life projections based on preliminary density and observed degradation.

Failure settings include surface polishing, micro-cracking, spalling at sides, and total floor tile dislodgement as a result of sticky deterioration or mechanical overload.

Source analysis frequently discloses installation mistakes, inappropriate grade selection, or unforeseen influence lots as primary contributors to early failure.

Life process expense analysis constantly demonstrates that regardless of higher initial expenses, alumina liners supply premium complete price of possession due to extensive substitute intervals, decreased downtime, and reduced upkeep labor.

4. Industrial Applications and Future Technological Advancements

4.1 Sector-Specific Executions Throughout Heavy Industries

Alumina ceramic wear linings are deployed throughout a wide range of industrial fields where product deterioration presents functional and economic challenges.

In mining and mineral handling, they safeguard transfer chutes, mill linings, hydrocyclones, and slurry pumps from rough slurries consisting of quartz, hematite, and other difficult minerals.

In power plants, alumina tiles line coal pulverizer air ducts, boiler ash receptacles, and electrostatic precipitator parts exposed to fly ash erosion.

Concrete suppliers make use of alumina linings in raw mills, kiln inlet areas, and clinker conveyors to fight the very abrasive nature of cementitious products.

The steel sector utilizes them in blast furnace feed systems and ladle shadows, where resistance to both abrasion and modest thermal loads is crucial.

Even in less conventional applications such as waste-to-energy plants and biomass handling systems, alumina ceramics supply durable security against chemically hostile and coarse products.

4.2 Arising Trends: Compound Systems, Smart Liners, and Sustainability

Current study focuses on improving the strength and performance of alumina wear systems via composite design.

Alumina-zirconia (Al ₂ O FIVE-ZrO ₂) composites leverage transformation strengthening from zirconia to improve fracture resistance, while alumina-titanium carbide (Al ₂ O FIVE-TiC) grades use enhanced performance in high-temperature gliding wear.

Another development involves embedding sensors within or beneath ceramic linings to check wear development, temperature level, and impact frequency– enabling anticipating upkeep and digital double integration.

From a sustainability viewpoint, the extended life span of alumina linings lowers material consumption and waste generation, lining up with round economic situation concepts in commercial operations.

Recycling of invested ceramic linings right into refractory aggregates or building and construction materials is likewise being checked out to minimize environmental footprint.

To conclude, alumina ceramic wear liners represent a cornerstone of contemporary commercial wear security innovation.

Their remarkable hardness, thermal security, and chemical inertness, incorporated with fully grown manufacturing and installment methods, make them indispensable in combating material destruction throughout heavy sectors.

As material scientific research advancements and electronic monitoring becomes more incorporated, the next generation of smart, resilient alumina-based systems will additionally enhance functional efficiency and sustainability in abrasive settings.

Provider

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality alumina al2o3, please feel free to contact us. (nanotrun@yahoo.com)

Tags: Alumina Ceramic Wear Liners, Alumina Ceramics, alumina

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us