In sectors where extreme temperature levels, chemical direct exposure, and mechanical anxiety assemble, ordinary products falter while crafted options flourish. The Alumina Porcelain Cooking Meal represents a course of innovative ceramics that goes beyond domestic images to end up being a crucial component in high-performance research laboratories, aerospace testing gears, metallurgical handling, and materials study. Crafted from high-purity light weight aluminum oxide, this dish embodies the marital relationship of ceramic science and precision production, delivering unparalleled thermal stability, chemical inertness, and dimensional uniformity. Its duty is not to serve dishes yet to enable reproducible experiments, regulated thermal cycles, and trusted containment in penalizing atmospheres. Recognizing the Alumina Ceramic Baking Recipe discloses just how material technology encourages progression throughout fields that shape our technological landscape.

1. The Material Foundations of Alumina Porcelain Baking Recipe

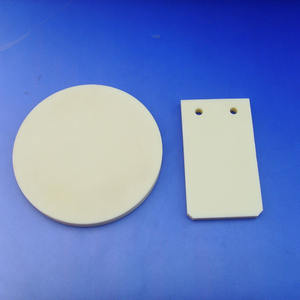

(Alumina Ceramic Baking Dish)

At the heart of the Alumina Ceramic Baking Dish exists aluminum oxide, a ceramic distinguished by remarkable hardness, electric insulation, and refractory ability. In its sintered type, alumina accomplishes an inflexible crystalline framework capable of standing up to continuous procedure above 1500 levels celsius without softening or flawing. This thermal endurance emerges from solid ionic bonds within the crystal lattice, which stand up to interruption also under quick home heating or cooling. Industrial-grade Alumina Ceramic Cooking Dishes commonly include purity degrees from 92 to 99.9 percent aluminum oxide, with small ingredients such as silica or magnesium oxide presented to help with sintering and control microstructure. These thoroughly selected structures identify crucial properties consisting of fracture durability, thermal shock resistance, and resistance to aggressive chemicals. Unlike steels, which perform heat and electrical energy readily, alumina serves as an insulator, making the meal ideal for applications calling for electrical isolation along with thermal efficiency. Its chemically inert nature makes certain that also when revealed to harsh acids, liquified salts, or responsive gases, the Alumina Porcelain Cooking Meal will neither break down nor infect the processed product. This foundation of durable physical and chemical characteristics clarifies why the dish is a trusted asset in environments where failure is not a choice.

2. Engineering the Alumina Porcelain Baking Recipe Via Precision Production

Creating an Alumina Ceramic Cooking Meal suitable for advanced commercial usage is a multi-stage process requiring precise control. It begins with ultra-fine powder preparation, where raw alumina is grated to submicron fragment dimension and blended with sintering help to make sure uniform distribution. Forming techniques differ with geometry and batch size; pass away pressing deals performance for basic types, while isostatic pressing applies uniform pressure for intricate contours, and slide casting permits detailed styles with liquid slurry deposition into porous mold and mildews. When formed, the environment-friendly body is dried out gradually to avoid cracking prior to entering a high-temperature heating system. Sintering happens at temperature levels typically between 1500 and 1700 levels celsius, where atomic diffusion integrates bits into a dense matrix. Crucially, the heating and cooling rates are programmed to decrease thermal slopes that can generate stress and anxieties resulting in cracks. After sintering, machining processes such as ruby grinding refine measurements and surface finishes to micron-level tolerances. Some variations obtain a vitreous polish to secure pores and improve resistance to liquid penetration, while others continue to be unglazed to maximize chemical resistance and thermal emissivity. Each Alumina Porcelain Baking Meal thus emerges as an item of securely handled science and ability, ready to perform dependably in rigorous setups.

3. Harnessing Thermal Habits for Controlled Industrial Processes

Thermal management is frequently the decisive consider high-end product testing and handling, and the Alumina Ceramic Baking Dish succeeds through its well balanced warm feedback. Its modest thermal conductivity enables gradual, uniform energy absorption, avoiding local overheating that could modify sample residential properties or skew dimension information. Simultaneously, its high volumetric heat capacity suggests it stores significant thermal energy, helping preserve stable temperatures despite brief environmental fluctuations. This home proves invaluable in processes such as controlled ambience sintering, stimulant activation researches, and thermal slope analysis, where even minor variations can jeopardize results. The low coefficient of thermal development of alumina gives exceptional resistance to thermal shock, allowing the Alumina Porcelain Baking Meal to sustain quick shifts from ambient to severe temperatures without fracturing. In research laboratory simulations of combustion atmospheres, aerospace thermal cycling examinations, and metallurgical warmth treatment trials, the dish acts as a secure system that shields both sampling and instrumentation. Designers count on its foreseeable efficiency to make repeatable experiments and scale processes from benchtop to pilot plant with self-confidence.

4. Chemical Inertness and Safety And Security in Demanding Applications

Industries ranging from semiconductor manufacture to nuclear research require vessels that will not introduce pollutants or respond with unsafe materials. The Alumina Ceramic Cooking Recipe fulfills this demand via near-total chemical inertness across a vast pH variety and in the existence of solvents, acids, and responsive intermediates. This non-reactivity safeguards both the stability of speculative samples and the safety and security of workers handling them. High-purity alumina is categorized as biocompatible and food-contact safe in managed contexts, however in commercial circumstances its importance lies in preventing unintended chemical interactions that might mask real product actions or produce toxic results. The surface area of the dish can be engineered to stand up to bond of liquified steels or thick polymers, alleviating post-process clean-up and decreasing cross-contamination dangers. Incorporated with its electrical protecting buildings, the Alumina Ceramic Baking Recipe makes it possible for safe handling of charged samplings and operation in high-voltage screening gears. These features make it essential where logical accuracy and ecological safety and security are paramount.

5. Varied Industrial Responsibility of Alumina Ceramic Cooking Meal

Much from a single-purpose item, the Alumina Porcelain Baking Recipe finds application throughout various areas that share a demand for high-temperature stability and chemical resistance. In materials research study, it works as a crucible and provider for sintering powders, expanding single crystals, and annealing alloys under regulated atmospheres. Aerospace engineers utilize it in testing components versus oxidative and thermal extremes, replicating trip reentry or engine exhaust conditions. Metallurgists use it for holding liquified non-ferrous metals and salts where steel or graphite would fall short. In the power field, it sustains solid oxide fuel cell research and battery material synthesis, supplying a neutral atmosphere for sensitive chemistries. Quality assurance labs rely upon its uniformity to produce equivalent outcomes across batches of tests. Even in emerging locations like additive manufacturing of ceramics and composites, the Alumina Porcelain Cooking Dish functions as a develop platform or debinding container, demonstrating convenience that bridges typical and frontier technologies. Its mechanical strength and dimensional precision enable accurate positioning within heating systems and reactors, helping with automation and high-throughput process.

6. Linking Product Efficiency to Operational Dependability

Choosing the Alumina Ceramic Cooking Meal for a commercial process is a choice rooted in dependability. Its resistance to creep– the tendency of products to warp under load at high temperature– ensures that geometry stays continuous over long direct exposures, preserving procedure uniformity. Put on resistance originates from its extreme hardness, which decreases erosion when unpleasant powders or granules are processed. Fatigue stamina allows repeated thermal cycling without building up damage, lowering lifecycle expenses and downtime. For makers, this translates right into less disturbances, tighter quality control, and expanded solution intervals. When incorporated right into verified treatments, the Alumina Porcelain Baking Meal becomes a quiet guarantor of reproducibility, an essential quality in study and production alike. Its ability to perform identically throughout various facilities enhances partnership and standardization in worldwide industries.

7. Progressing Alumina Porcelain Baking Recipe for Next-Generation Needs

( Alumina Ceramic Baking Dish)

Technology remains to press the capacities of the Alumina Porcelain Baking Dish toward new frontiers. Researchers are developing nano-structured alumina composites that improve strength while retaining high-temperature efficiency, minimizing the threat of breakable crack in demanding operations. Crossbreed styles integrating other innovative porcelains such as zirconia or silicon carbide extend applicability to a lot more destructive or mechanically intense settings. Additive manufacturing strategies now allow complicated recipe geometries that optimize warmth circulation patterns for particular procedures. Efforts to reduced sintering temperatures with advanced powder handling and different binders aim to lower power intake and ecological impact. Integration with sensor systems could enable real-time tracking of thermal and chemical conditions inside the meal, feeding information right into automatic process controls. As sectors go after higher effectiveness, cleaner manufacturing, and much more accurate experimentation, the Alumina Ceramic Cooking Dish will advance as a smarter, greener, and more resistant enabler of technical innovation.

TRUNNANO chief executive officer Roger Luo stated:”The Alumina Porcelain Baking Recipe will progressively combine high-performance ceramic science with intelligent design to drive accuracy, sturdiness, and sustainability in the most requiring commercial and study applications.”

8. Vendor

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality white alumina, please feel free to contact us.

Tags: Alumina Ceramic Baking Dish, Alumina Ceramics, alumina

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us